Flexible Intermediate Bulk Containers (FIBC Bags) are large, durable sacks used extensively for the transportation and storage of bulk materials. Their versatility and efficiency make them indispensable across a wide range of industries. In the agricultural sector, FIBC bags are commonly used to store and transport grains, seeds, fertilizers, and animal feed. Their large capacity allows farmers and suppliers to move significant quantities of product with ease, reducing the need for multiple smaller containers and thereby improving logistics efficiency. Leopack’s FIBC bags are designed with the highest standards of quality, ensuring that your bulk materials are transported securely and without contamination, helping you overcome any challenges related to bulk handling.

In the chemical industry, FIBC bags are vital for handling powdered, granular, or flaked chemicals. These bags are specifically designed to prevent contamination and protect the integrity of the contents. Leopack’s FIBC bags offer enhanced protection with superior material strength, ensuring that even hazardous materials are transported safely. The construction sector also benefits from FIBC bags, using them to transport sand, gravel, cement, and other heavy materials. Leopack’s commitment to quality ensures that their FIBC bags are capable of handling substantial weight, providing peace of mind that your materials will arrive intact and unspoiled. Furthermore, in the food industry, FIBC bags are utilized for bulk packaging of ingredients like sugar, flour, and spices, ensuring that large volumes of food products can be handled efficiently and hygienically. Leopack’s precision manufacturing guarantees that our bags meet the highest food safety standards, helping you maintain the integrity of your products.

Safety is paramount when it comes to handling bulk materials, and FIBC bags are engineered with multiple safety features to ensure secure usage. These bags are typically made from woven polypropylene, a material known for its high tensile strength and resistance to wear and tear. Leopack’s FIBC bags are manufactured using the best quality materials, offering unmatched durability and reliability, which is essential for preventing accidents during lifting and transportation.

Additionally, FIBC bags often come with reinforced lifting loops, enabling safe handling with forklifts or cranes. The loops are designed to bear the weight of the bag without tearing, which is crucial for preventing accidents. Leopack’s meticulous design and testing processes ensure that each bag can withstand the rigors of industrial use, providing an added layer of safety for your operations.

Another significant safety feature is the anti-static or conductive design available in specific types of FIBC bags. These variants are essential when transporting flammable or explosive materials, as they prevent the buildup of static electricity that could lead to sparks and subsequent fires or explosions. Leopack’s expertise in producing high-quality anti-static FIBC bags means you can trust our products to handle even the most sensitive materials. Some FIBC bags are also equipped with liners to provide additional protection against moisture, contamination, and air penetration, further safeguarding the contents. Leopack’s advanced manufacturing techniques ensure that these liners are perfectly integrated, providing comprehensive protection and peace of mind.

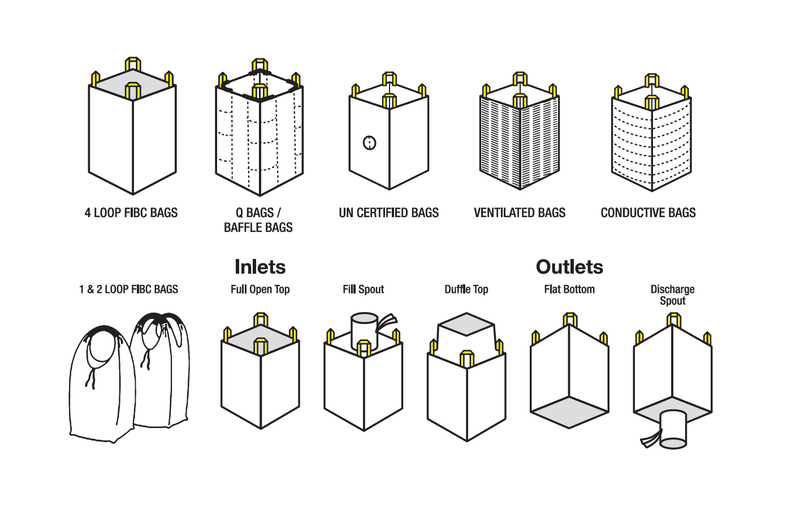

FIBC bags come in several types, each tailored to meet specific industrial requirements. Leopack offers a full range of FIBC bag types, designed to meet the diverse needs of various industries. The most common types include:

Type A FIBC Bags: These are standard FIBC bags made from plain-woven polypropylene or similar materials. They are used for transporting non-flammable products that do not require special handling to prevent static electricity buildup. Leopack’s Type A bags are built with the highest quality standards, ensuring that your non-flammable materials are transported safely.

Type B FIBC Bags: Similar to Type A, but with a lower breakdown voltage, Type B bags are used to transport dry, flammable powders in environments where there is no risk of explosive dust or gases. Leopack’s attention to detail in the manufacturing of Type B bags ensures that your flammable powders are handled with the utmost care.

Type C FIBC Bags (Conductive Bags): These bags are made from electrically conductive fabric, often incorporating conductive threads woven into the material. Type C bags are essential when transporting flammable powders or handling materials in environments where combustible gases or dust are present. They must be grounded during the filling and discharging processes to prevent the buildup of static electricity. Leopack’s Type C bags are rigorously tested to ensure they meet all safety standards, providing a reliable solution for your hazardous material needs.

Type D FIBC Bags (Anti-Static Bags): Type D bags are designed to safely transport flammable materials without the need for grounding. These bags are made from anti-static or static dissipative fabrics that prevent the buildup of static electricity and safely dissipate it without causing sparks. Leopack’s Type D bags are engineered with cutting-edge materials, providing a robust solution for your anti-static needs.

Ventilated FIBC Bags: These bags feature breathable fabric, allowing air to circulate through the bag. Ventilated FIBC bags are used primarily for transporting products that require airflow, such as potatoes, onions, and other agricultural produce, to prevent spoilage. Leopack’s ventilated bags are crafted to provide optimal airflow, ensuring your produce stays fresh during transport.

Baffle Bags: Equipped with internal baffles, these bags maintain a square shape when filled, maximizing storage space and stability during stacking. Baffle bags are used in situations where efficient space utilization is critical, such as in shipping containers or warehouse storage. Leopack’s baffle bags are designed with precision, ensuring that your storage and transportation operations are as efficient as possible.

Single-Loop and Two-Loop FIBC Bags: These bags are designed for ease of handling and are ideal for specific applications where quick and efficient loading and unloading are required. They are commonly used in industries that handle granular materials like salt, sugar, and sand. Leopack’s single-loop and two-loop bags are constructed with superior materials, offering unmatched durability and ease of use.

Custom FIBC Bags: In addition to standard types, FIBC bags can be customized according to specific needs. Customization options include the size, shape, and material of the bag, as well as additional features like liners, special coatings, and custom printing for branding or labeling purposes. Leopack’s custom FIBC solutions are tailored to meet your exact specifications, ensuring that your unique needs are fully addressed.

FIBC bags are indispensable in modern industrial operations, offering a safe, efficient, and versatile solution for the transport and storage of bulk materials. Leopack’s FIBC bags stand out for their exceptional quality and adaptability, ensuring that every challenge related to bulk handling is effectively met. Their various types and tailored designs ensure that there is an appropriate FIBC bag for virtually every application, from agricultural produce to hazardous chemicals. The robust safety features embedded in each bag type, including anti-static properties and reinforced lifting loops, ensure that materials can be handled without compromising safety. Moreover, the customization options available mean that businesses can optimize their bulk handling processes to meet specific operational needs with the help of Leopack’s expert guidance and superior products.

For more information on FIBC bags, or to discuss your specific requirements, please contact Leopack’s sales team at +91 8128599591 or email us at sales@leopack.in. Our facility is located at 3002/F/1, 113, GIDC Ankleshwar – 393002.

Specialize in precision Packaging Solutions Utilizing High-Quality Woven and Non-Woven Materials, HRCT Boxes and Sheets.